Quality

Dream Plast is a quality conscious organization. Our Quality

Policy is:

"We all at Dream Plast India Pvt. Ltd., are committed to

providing consistent quality products and services to our

customers. We shall continually review and improve the

established Goals and Quality Management Systems to enhance

Customer Satisfaction".

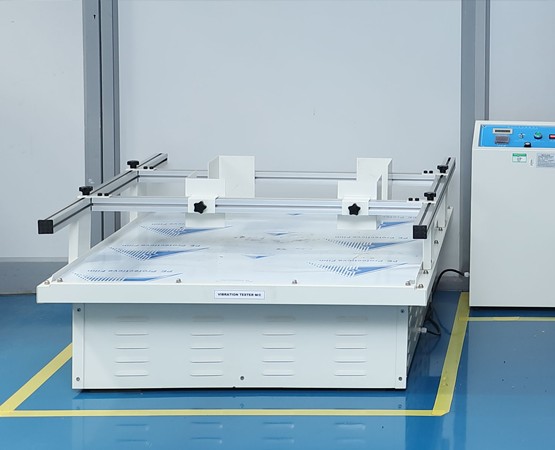

Besides the routine incoming and in-process checks, we also

perform a number of tests in order to guarantee the final

product quality, such as drop test, transit test, smell

test, torque test, force test, sharp point test, moisture

test, aging test, pthalates test, cross cavity test etc. Our

testing labs are well equipped with instruments, gauges and

equipment to perform these tests.

Traceability is important to our customers. In accordance

with the expectation of our customers we have built

processes and documentation such that in the event of

detection of a non-conformance, we are able to trace back

right upto the raw material stage and in the shortest

possible time.

Based on the experience that we have gained working with

several customers, we have created our own Vendor Manual. We

maintain an approved vendor list and frequently perform

vendor audits in order to ensure consistency of conditions

and supplies is maintained.

Dream Plast is also working towards establishing a Chemical

management system, considering the risks associated with the

contamination by hazardous chemicals such as phthalates and

heavy metals.